TOUCH SCREEN CONTROLSYSTEM

Sample Screens (may include optional items)

Overview Screen Set Points ScreenAlarm Screen

?? Robust, Windows based platform

?? Password controlled access to programming screens

?? Easy operator interface

?? Alarm Package included in software

?? Recipe Capability

?? Touch screen displays and sounds alarms when machine controls are out oftolerance

?? Light Tower

?? Auto Start / Stop with photo sensor at entrance

?? 12” LCD Touch screen

STANDARD FEATURES inorder of MODULE CONFIGURATION

LOAD

?? Auto Start / Stop with sequential power on / off to pumps and blowers

?? Emergency Stop Button

?? Personnel Grounding Socket

?? 12” Fixed Entrance Extension

SEPARATION STAGE -OR-OPTIONAL PREWASH STAGE (Specify at time ororder)

?? Recaptures atomized wash water particles, reducing chemistry loss

AIR CURTAIN STAGE

?? Air curtain recaptureswash water particles and directs them back into wash tank

WASH STAGE FLOOD BOXCONFIGURATION

?? 4 Incoloy 13 kW Immersion Heaters mounted on accessible front bulkhead [See Figure 1]

?? Completely submerges the circuit board under the wash fluid

?? Penetrates under low standoff components

?? Penetrates between components on high density printed circuit boards

?? Upper and Lower spray bars within the Flood Box

?? Conveyor remains level through the Flood Box

?? Over Temperature Protection

?? Redundant low liquid level protection

?? Automatic Fill with Level Control

?? Auto Chemistry System -- includes metering pump controlled by flow sensor, which

delivers balanced chemistry to thewash section (Optional)

?? Two Patented Barrier Water Knives powered by a dedicated 10 HP pump

?? 4 Spray Modules with Quick Disconnect Spray Bars (TOP) [See Figure 2]

?? Independent Gate Valves Spray Pressure Control for upper and lower spraybars

?? Rear pressure gauges for upper and lower spray bars

?? High Performance 15 H.P. HPHV Centrifugal Stainless Steel Pump

?? VFD Pump Control

?? Stainless Steel High Pressure Plumbing

?? Removable Low Loss Pump Intake Screen Strainer (60 Mesh - .01”)

?? Easy Access Catch Screen [See Figure 1]

?? Removable Access Ports for Tank cleaning

?? Transparent interior slide panel lid and exterior access tempered glasswindow for inprocess

inspection

?? Independent Tank DrainValve

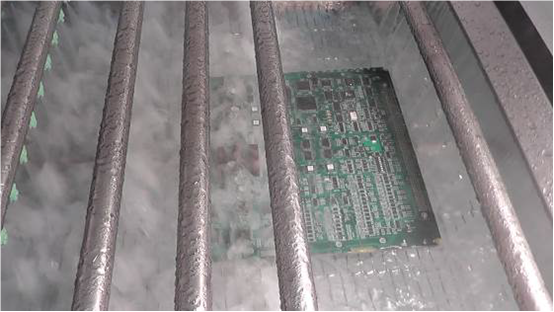

Flood Box

Flood Box

Printed Circuit Board

traveling through the

Flood Box

ANTI-DRAGOUTAIR KNIFE STAGE

?? Custom Two Upper and One Lower Air Knife

?? Increased capability to reduce Liquid Dragout from Washtank

?? Driven by dedicated Air Knife Blower

?? Tempered glass window for In-Process Inspection

?? 15 HP Blower with Self Tensioning Belt to power DragoutAir Knives

ISOLATIONRINSE STAGE

?? Prevents chemical drag out from wash to rinse tank

?? 2 Quick Disconnect Spray Bars [ See Figure 2]

?? One adjustable upper and lower Air Knife Tube

?? Increases liquid penetration under components

??Outside water supply controlled and monitored by valveand flow meter

with direct flow todrain

OR

??Water supplied from rinse pump controlled and monitoredby valve and flow meter

with direct flow todrain

?? One Upper and One Lower Air Knife Tube (post isolationrinse)

?? Transparent interior slide panel lid and exterior accesstempered glass window for inprocess

inspection

Flood Box

Flood Box

Printed Circuit Board

completely submerged

within the Flood Box

RECIRCULATING RINSESTAGE FLOOD BOX CONFIGURATION

?? 4 Incoloy 13 kW Immersion Heaters mounted on accessible front bulkhead [See Figure 1]

?? Over temperature Protection

?? Redundant low liquid level protection

?? Automatic Fill with Level Control

?? Two Patented Barrier Water Knives powered by a 10 HP pump

?? 2 Spray Modules with Quick Disconnect Spray Bars (TOP) [See Figure 2]

?? Independent Gate Valve Spray Pressure Controls for upper and lower spraybars

?? Rear pressure gauges for upper and lower spray bars

?? High Performance 15 H.P. HPHV Centrifugal Stainless Steel Pump

?? VFD Pump Control

?? Stainless Steel High Pressure Plumbing

?? Removable Low Loss Pump Intake Screen Strainer (60 Mesh - .01”)

?? Easy Access Catch Screen [See Figure 1]

?? Removable Access Ports for Tank Cleaning

?? Transparent Interior slide panel lid and exterior access tempered glasswindow for in

process inspection

?? Independent Tank Drain Valve

?? Direct to drain or cascade

FINAL RINSE STAGE

?? 1 Spray Module with Quick Disconnect Spray Bars [See Figure 2]

?? Nozzle Spray is controlled and monitored by valve and flow meter

?? Drag Out Air Knife Removes and Flushes Rinse Water

?? Removable Access Ports for Tank Cleaning

?? Transparent Interior slide panel lid and exterior access tempered glasswindow for in-process

inspection

?? Easy access catchscreen [See Figure 1]

DRYER STAGE

?? 2 Air Knife Modules each with 2 Upper and 1 Lower Air Knives

?? 2 each High Performance 15 HP Turbine Air Blower with Self Tensioning Belt

?? Slide out Blowers for easier access [SeeFigure 3]

?? Exterior Tempered Glass Window for In-process Inspection

?? Insulated Blower and Air Knife compartments for lower decibel operation,complying with

OSHA Standards

?? Custom Designed Stripping Air Knives for High Efficiency drying [See Figure 4]

?? Height & Angle Adjustable Upper Air Knives

?? Angle Adjustable Lower Air Knives

?? Double Paned Glass Viewing Windows for Noise Reduction

?? Dryer Section utilizesnon-recirculating air to reduce humidity in drying chamber

DRYER STAGE

?? 2 Air Knife Modules each with 2 Upper and 1 Lower Air Knives

?? 2 each High Performance 15 HP Turbine Air Blower with Self Tensioning Belt

?? Slide out Blowers for easier access [SeeFigure 3]

?? Exterior Tempered Glass Window for In-process Inspection

?? Insulated Blower and Air Knife compartments for lower decibel operation,complying with

OSHA Standards

?? Custom Designed Stripping Air Knives for High Efficiency drying [See Figure 4]

?? Height & Angle Adjustable Upper Air Knives

?? Angle Adjustable Lower Air Knives

?? Double Paned Glass Viewing Windows for Noise Reduction

?? Dryer Section utilizesnon-recirculating air to reduce humidity in drying chamber

CONVEYOR

?? Full 18” Process Width

?? Conveyor rail cutouts at spray bar and air knife locations

?? Lower Stainless Steel (302), .375 pitch

?? Upper Stainless Steel (302), .375 pitch (Optional)

?? Custom belts with Pockets, Lanes, or Coatings (Optional)

?? Drive protected by Slip Clutch

?? Conveyor is grounded for ESD Protection

?? Return Conveyor Belt routed outside of rinse and wash modules

?? Uni-Drive Top & Bottom Belts (Single Drive Motor) with Optional Top Belt

?? Standard 3” product clearance

EXHAUST

?? Concealed Integral Ducting

?? Three 10” External Exhaust Ports with Dampers

?? Reclamation Exhaust System with Coalescing Screen for the lowest chemistryloss is the

industry

SPECIFICATIONS

ELECTRICAL: 480 VAC 3PHZ Standard (380 VAC Optional)

EXHAUST: 1200 CFM @ 1.5" SP Per Stack with Damper ( 3 stacks)

WATER INPUT: 4.5 – 7.5 GPM depending on options and configuration

PRODUCT CLEARANCE: 3.0”

WEIGHT: 4,800 lbs. Approx.

WIDTH: 68.6"

HEIGHT: 62.4 – 64.9" (adj.)

LENGTH: 299"

BELT HEIGHT: 35 -37" (adj.)